Material Preparation

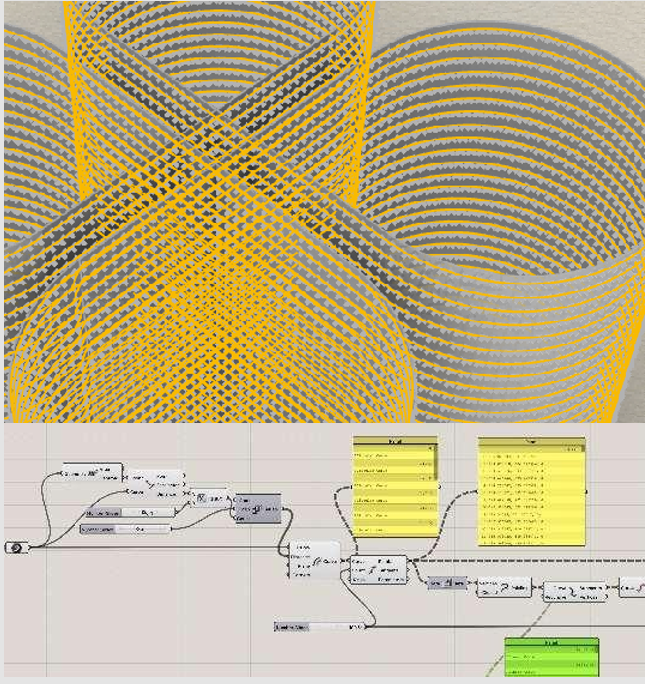

parametric design

3D printing

Finished product 1

Finished product 2

"Junction" regenerated ceramic humidifier YiDesign

In PPT, the work is introduced in detail from the aspects of materials; Design; Process; Sustainability, etc.

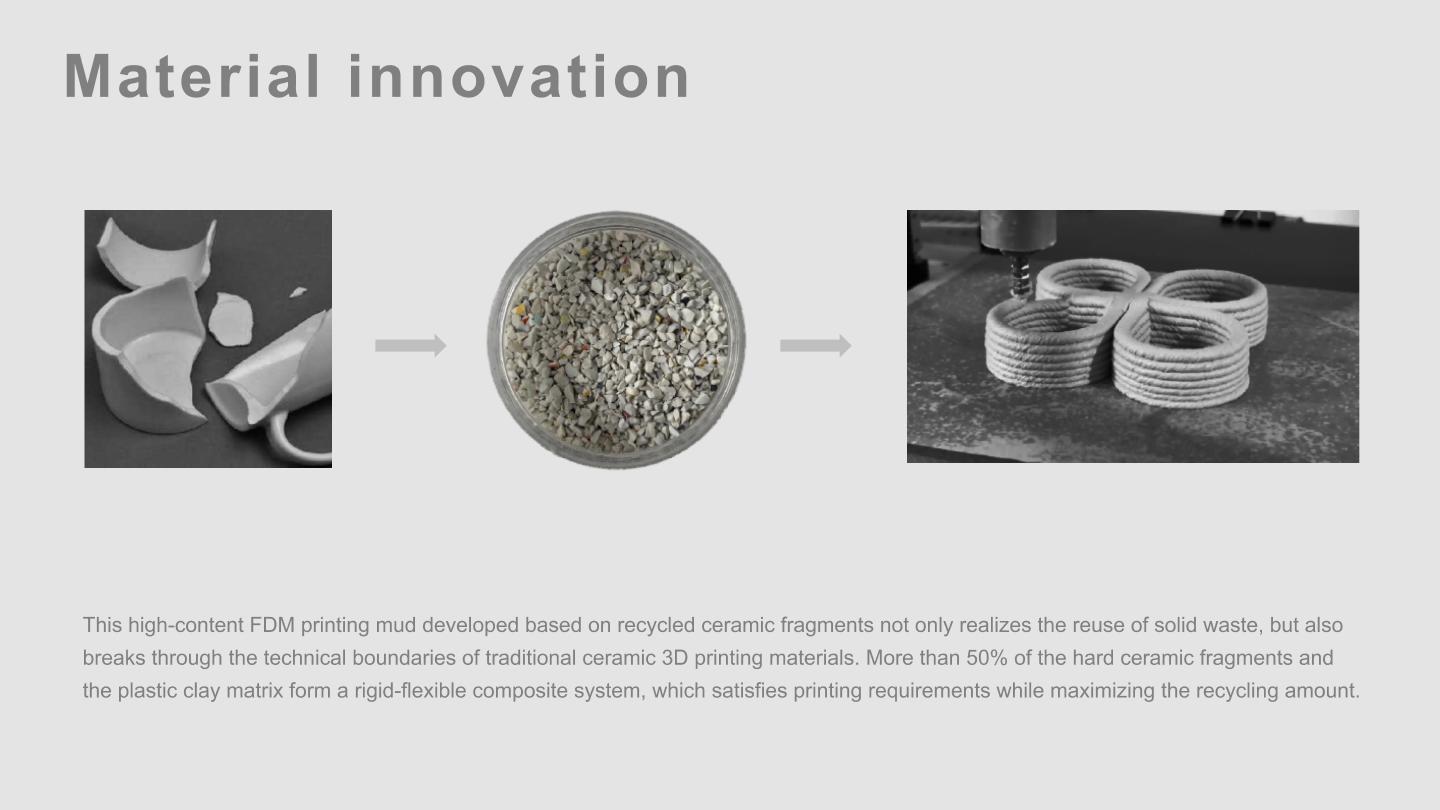

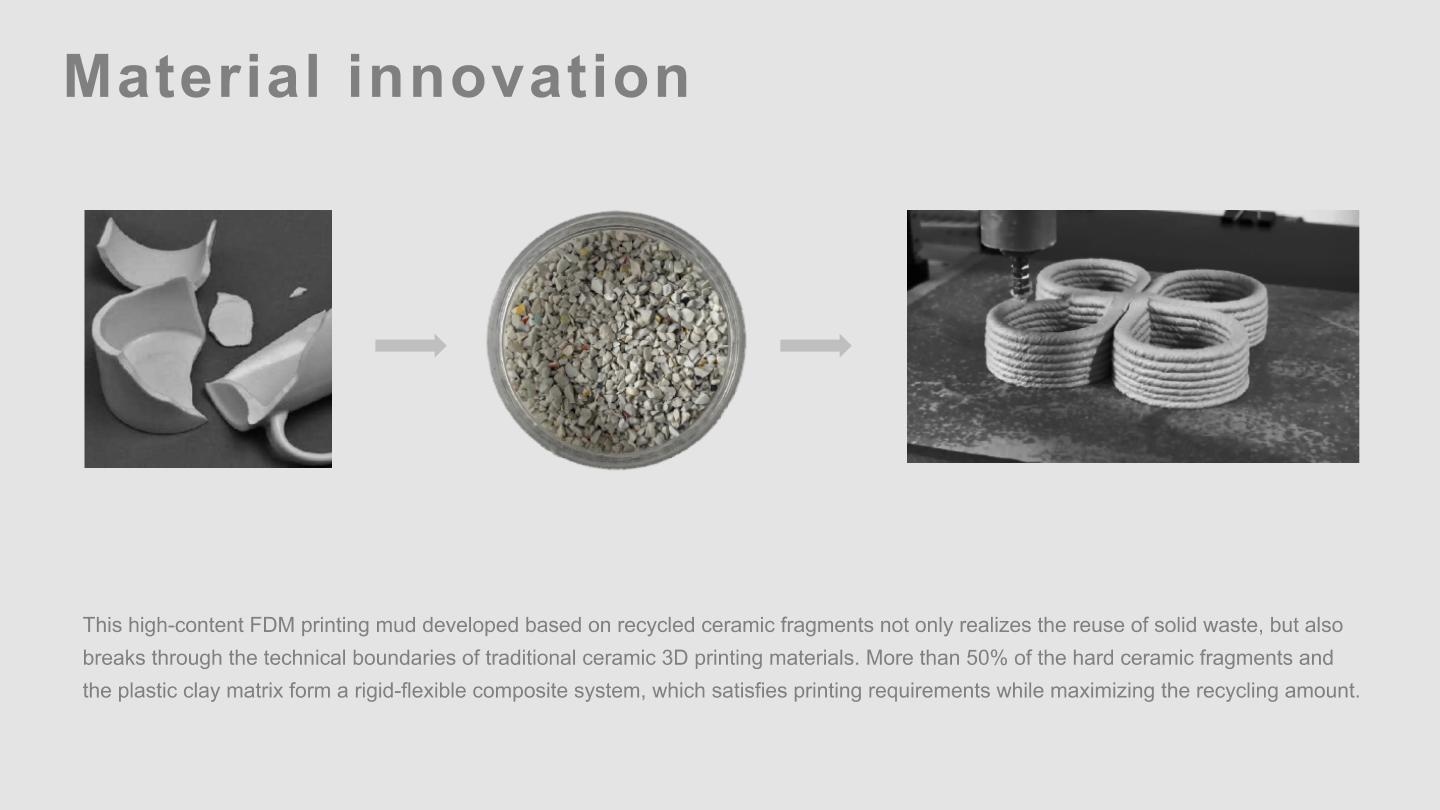

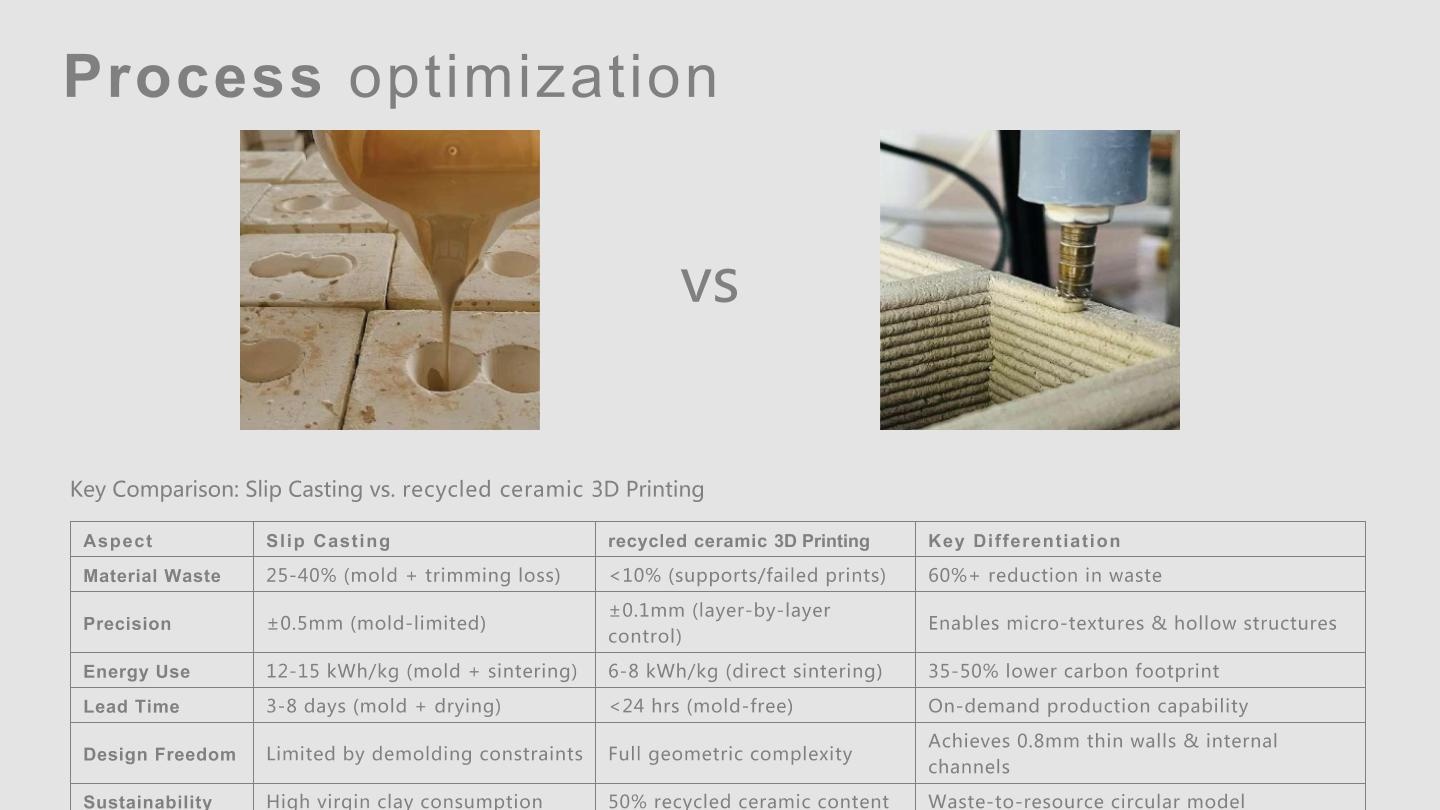

Recycled ceramic 3D printing process

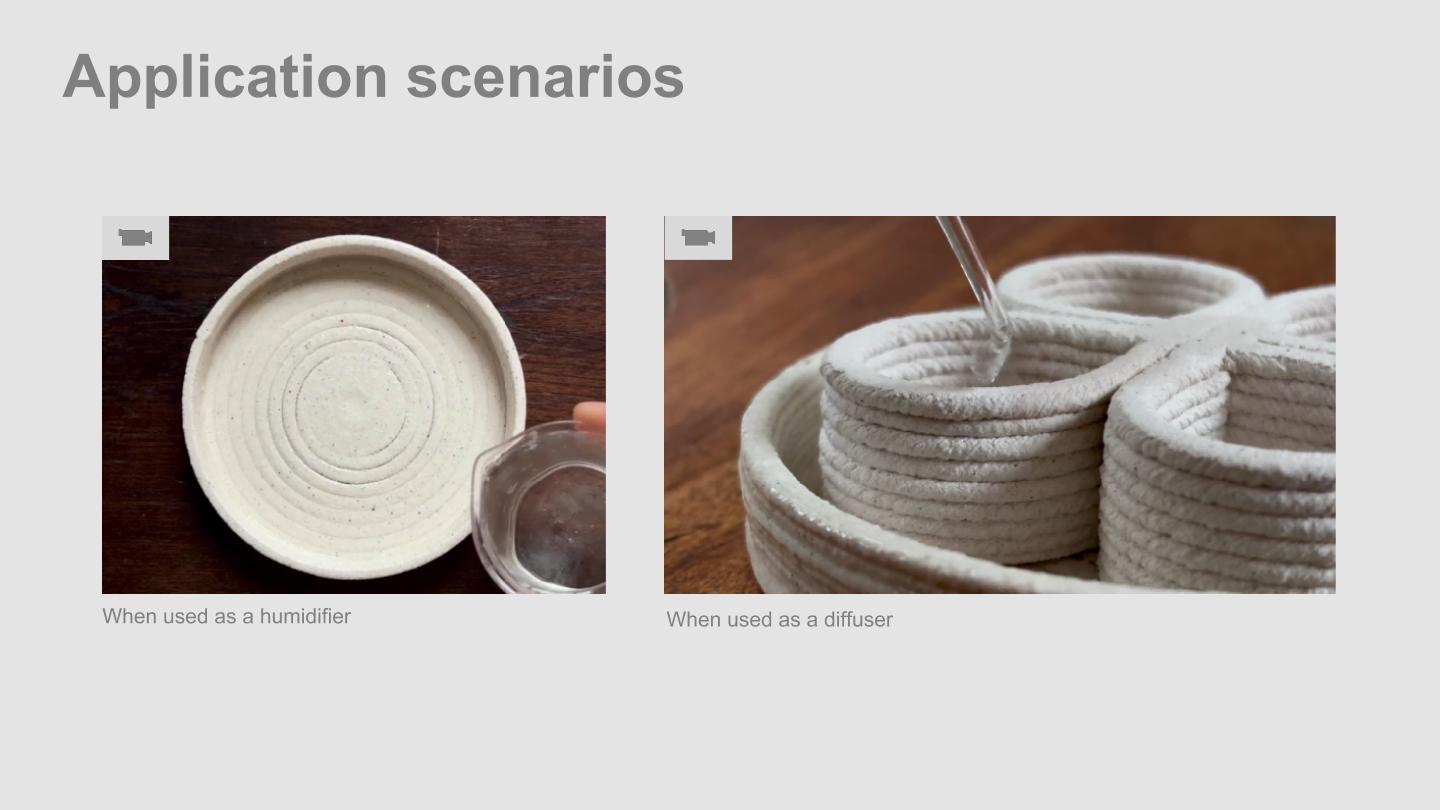

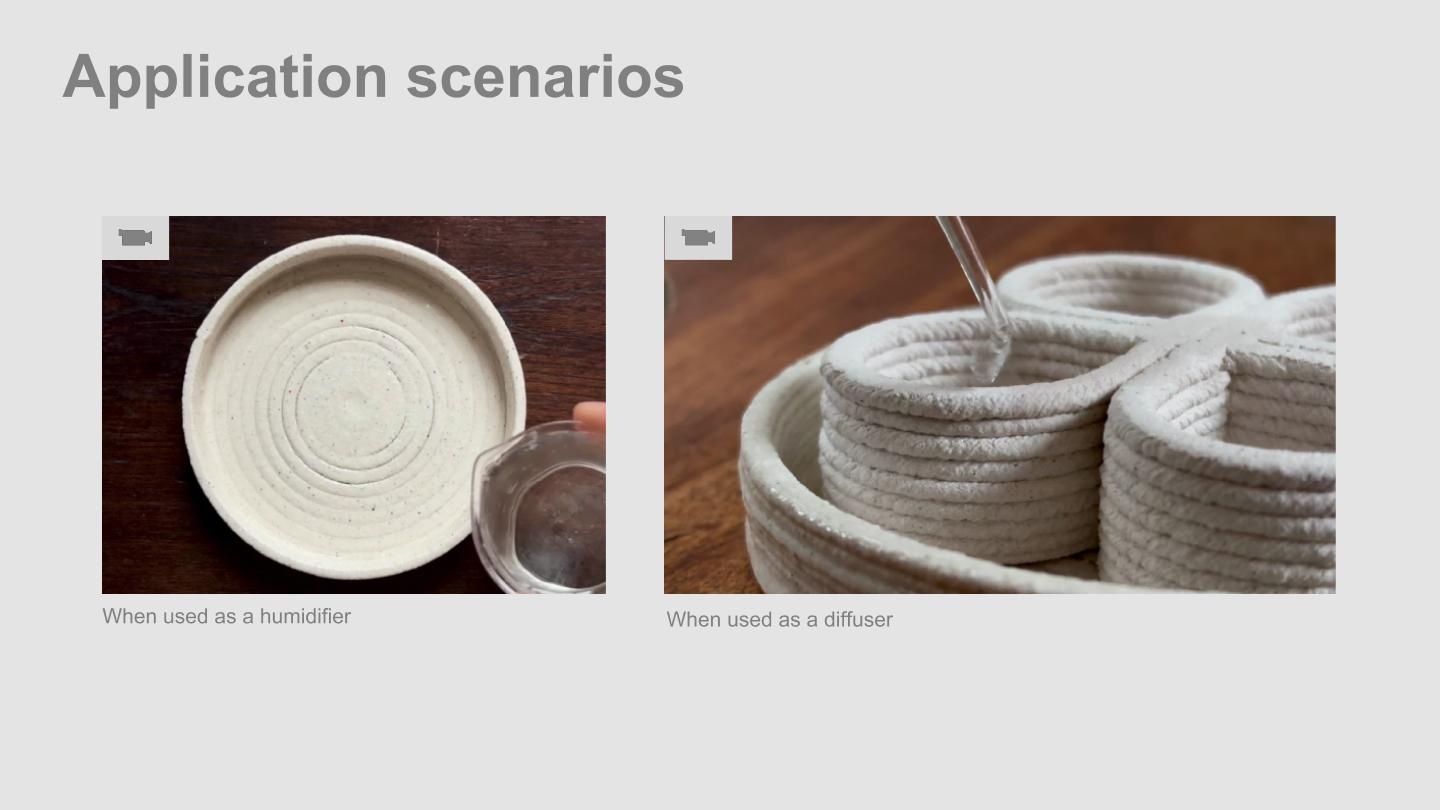

Humidifier use scene

"Knot" regenerative ceramic humidifier-let the old porcelain to regain the life of breathing

In the exploration of the balance between the city and nature, the humidifier reinterprets the symbiotic relationship between everyday objects and space with the regeneration and transformation of discarded ceramics. This plug-in-free desktop humidifier integrates the concept of sustainability into every interaction between water molecules and air through the most authentic "breathing" characteristics of ceramics.

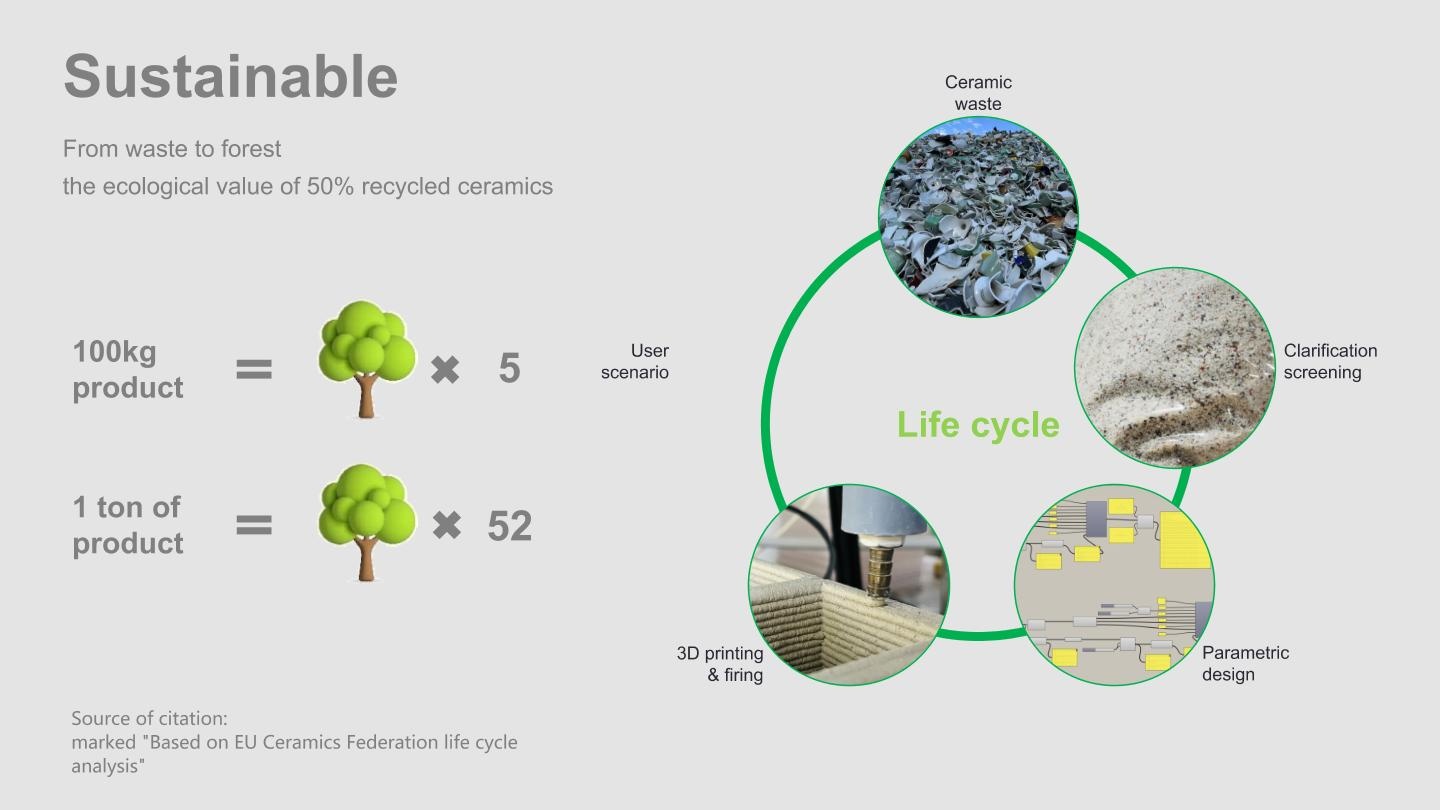

The core of the material is broken into 0.1-2mm particles by multi-stage crushing of recycled ceramic fragments, and remolded with natural mineral base material to form a stable porous structure in the secondary firing at 1200 ℃. Each piece of utensils contains more than 50% recycled ceramic components, and thousands of micron-sized pores inside it form a natural "water delivery channel", which independently adsorbs and stores water through capillary action, and then uniformly releases humidity in the form of natural evaporation, with an average daily water consumption of only 200ml. Compared with the electronic humidifier, the whole 0 power consumption, no noise, no white fog, in silence to restore the most healthy way of humidity regulation.

The body is designed with a porous structure: when immersed in clear water, it is a humidifying device that works silently; after dropping aromatherapy essential oil, the ceramic pores automatically absorb the liquid and release the aroma, transforming into a natural diffuser. The flat design of the plain blank body is suitable for a variety of life scenes: on the desk, it is an invisible assistant to relieve the dryness of the air-conditioned room; In the home space, it is matched with a few fresh-cut branches to form a micro-ecological device. During meditation, dripping citrus essential oil can create a relaxing field.

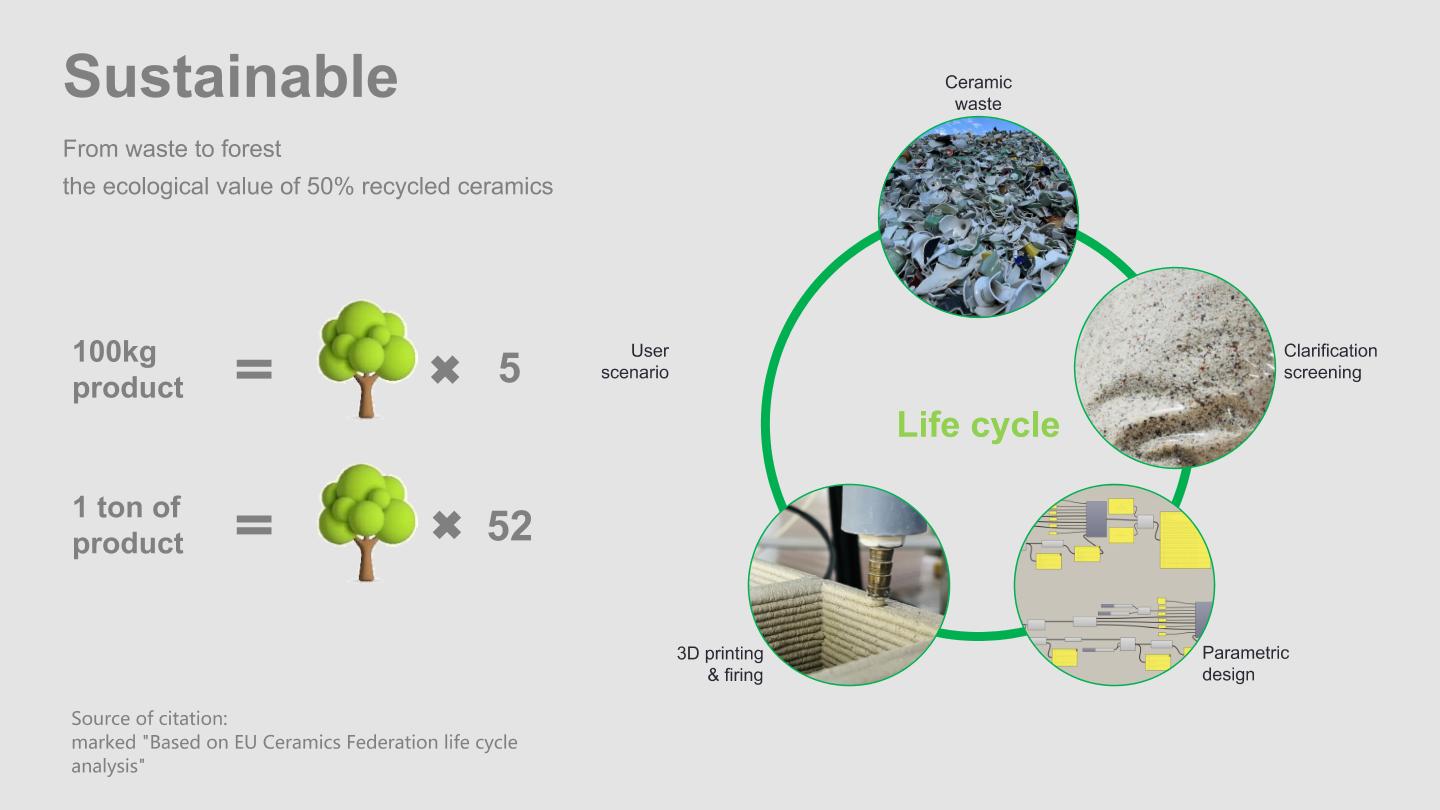

Each product consumes about 0.36kg of ceramic waste, and the firing energy consumption is 40% lower than that of traditional ceramics. When the user touches the vaguely raised regenerated porcelain grains on the surface of the device, what his fingertips cross is not only the texture of the material, but also a story of the dignity of the waste. This perceptible circular narrative makes environmental protection no longer a concept, but a life declaration that can be touched, used and spread.

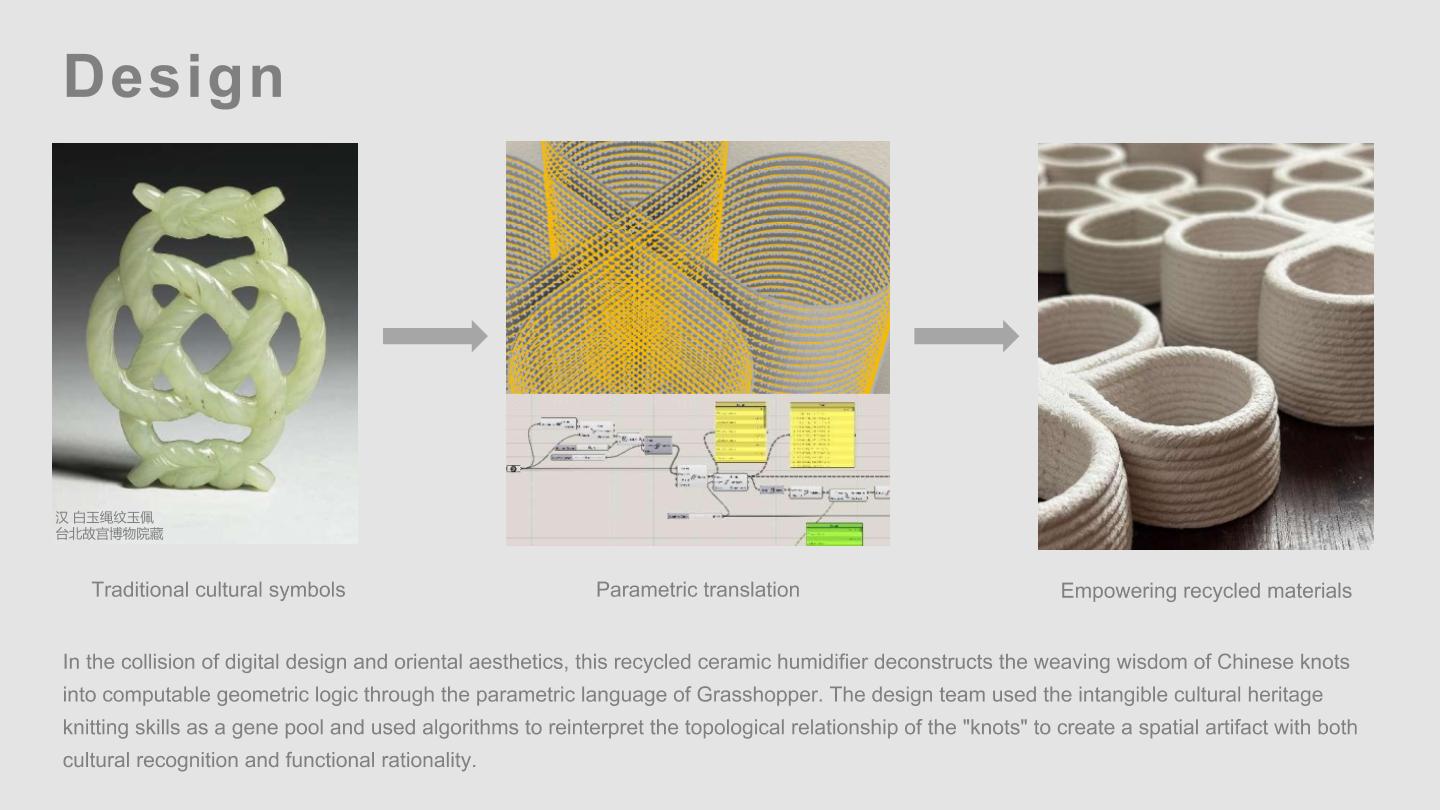

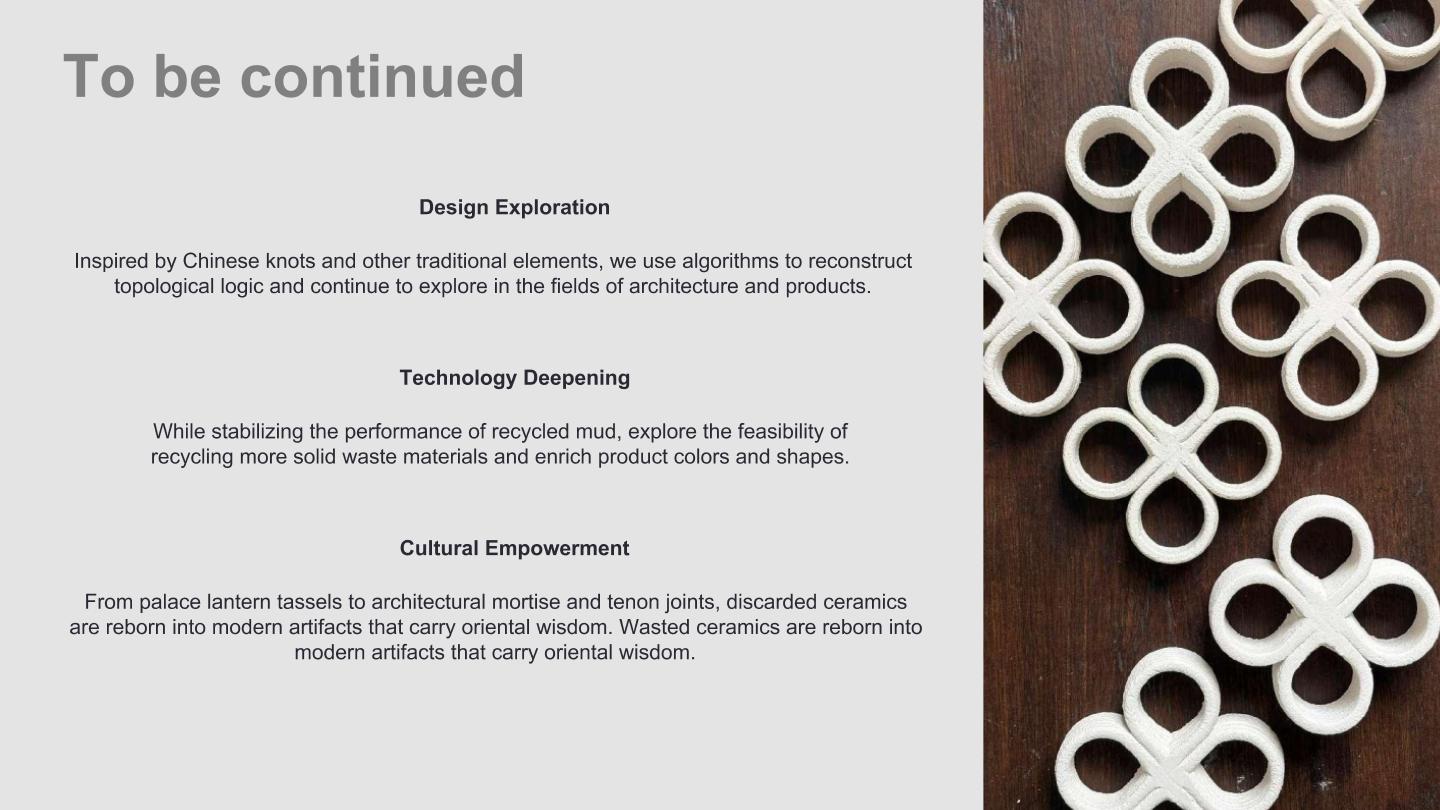

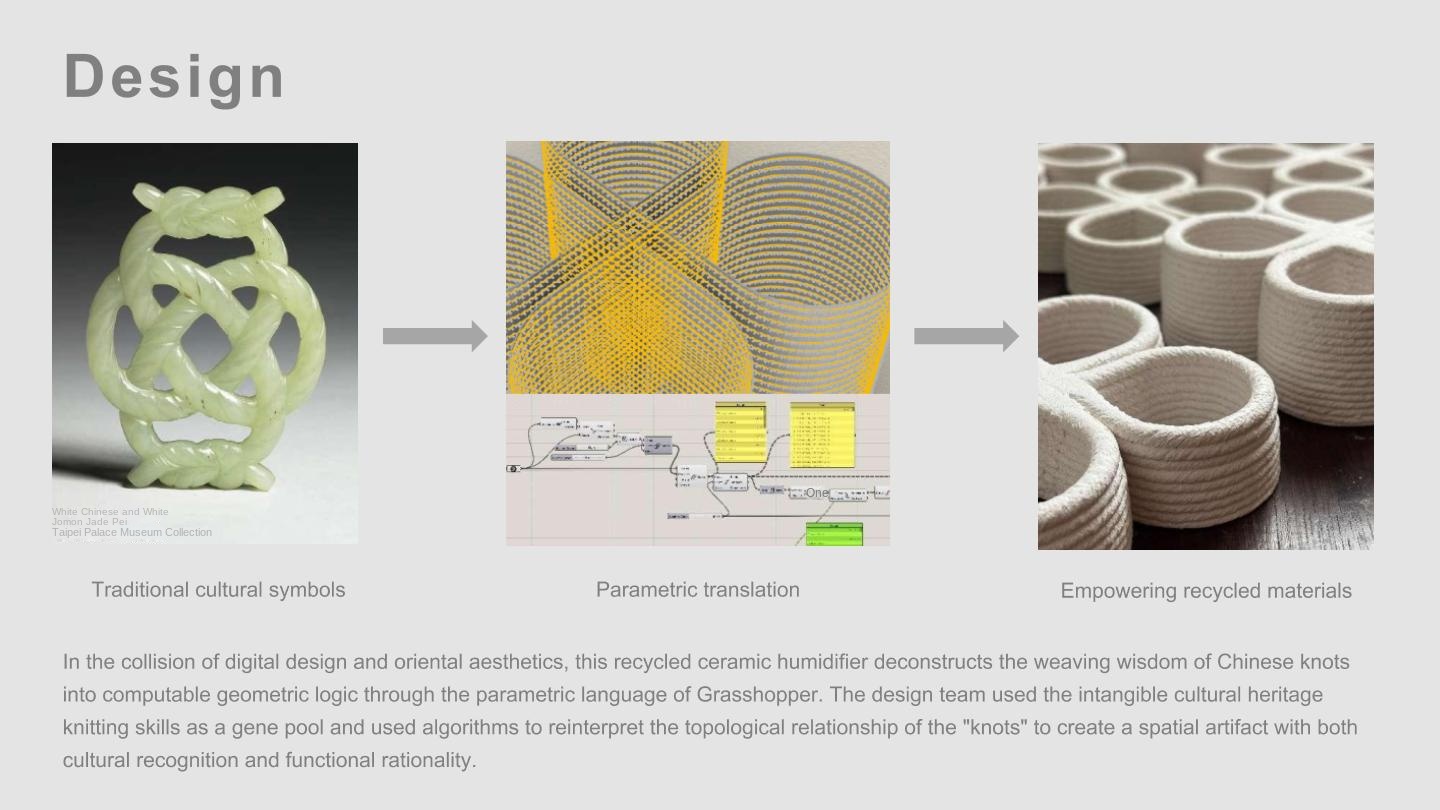

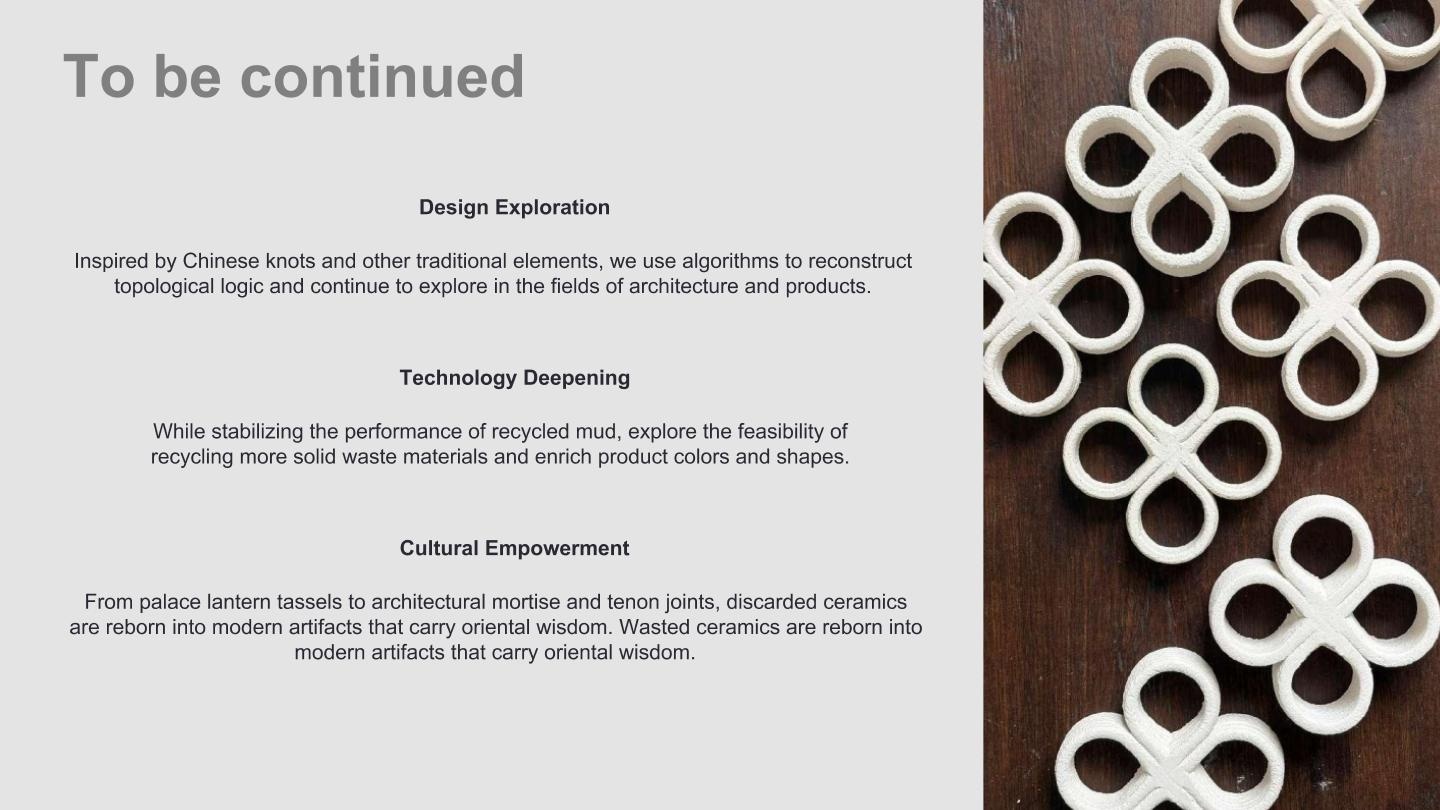

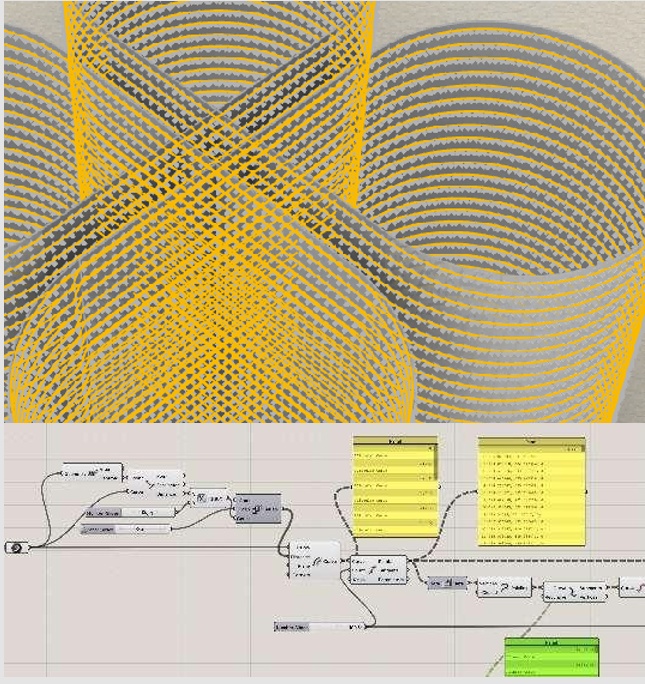

"Knot" recycled ceramic humidifier with digital design language, reinterpreted the essence of traditional Chinese weaving art. Through the parametric design tool Grasshopper, we transformed the "three-leaf pattern" of the Chinese knot into a three-dimensional ceramic structure, creating a humidifier shape with both functionality and visual tension.

The design is inspired by the weaving logic of Chinese knots and uses Grasshopper algorithms to generate interwoven three-dimensional grids. The direction, thickness and node connection of each "knot" have been accurately calculated, which not only retains the flow rhythm of traditional weaving, but also endows it with the rational beauty of modern geometry. Ceramic wires are stacked in layers during printing to form a hollow structure between virtual and real phases, which not only ensures the stability of the utensils, but also realizes efficient water evaporation and air circulation.

Under the parametric control of the Grasshopper, micro-protrusions are specially designed at the nodes of the woven structure to simulate the tactile details of hand-woven. From a distance, it is as simple as hemp rope, while from a close look, it presents the precision texture of digital manufacturing. This "digital hand-made" design language makes the cold technology and the warmth of traditional craftsmanship perfectly integrated.

The design transforms the two-dimensional plane patterns of Chinese knots into three-dimensional structures through parametric tools, which is not only a digital translation of intangible cultural heritage, but also a contemporary interpretation of traditional crafts. The interwoven lines are not only the expression of aesthetics, but also the core of function-the capillary network formed by the grid structure, so that the moisture can be evenly distributed and naturally evaporated, and the humidification function without power drive is realized.

"Knot" recycled ceramic humidifier with parametric design as a bridge, the wisdom of oriental weaving art into modern manufacturing, using digital language to tell the traditional story, so that each "knot" has become a link between the past and the future.

YiDesign group design is an environmental technology company with small production lines and independent research and development laboratories. Our mission is not only to solve the problem of ceramic waste management in China, but also to make ceramic recycled materials into green, sustainable and circular products that can be applied to construction, art and commercial products. Compared with traditional building materials, ceramic recycled materials designed to ensure performance at the same time, pay attention to reduce carbon emissions, and use less natural resources in the production process.